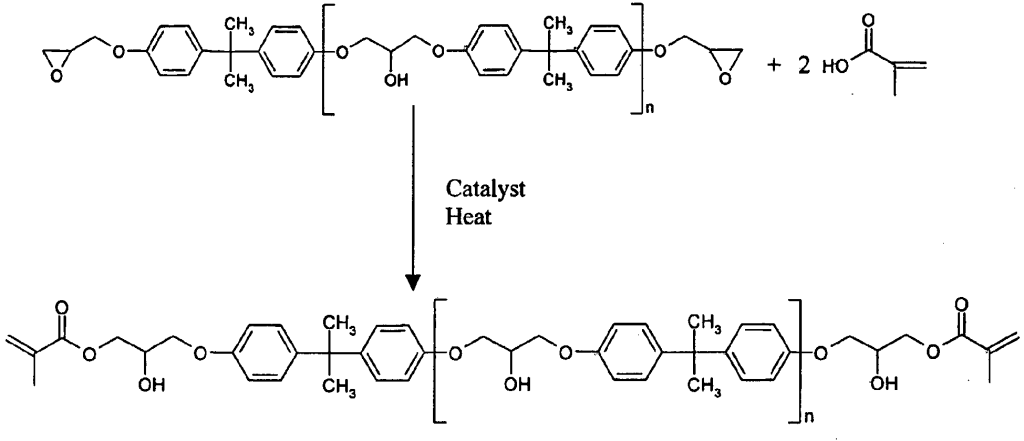

Epoxies can be converted to vinyl ester resin through esterification with acidic catalysts creating an intermediate product with mechanical strengths lower than that of epoxy resins but greater than polyester.

Epoxy vinyl ester resin chemical resistance.

Are low styrene monomer bisphenol a epoxy vinyl ester resins with mechanical thermal and chemical resistance properties between derakane 411 and derakane 470 resins.

Polives 721 epoxy novolac based vinyl ester resins are designed to provide exceptional thermal and chemical resistance.

Vinyl ester resins offer in general excellent resistance to acids alkalis hypochlorites and many solvents.

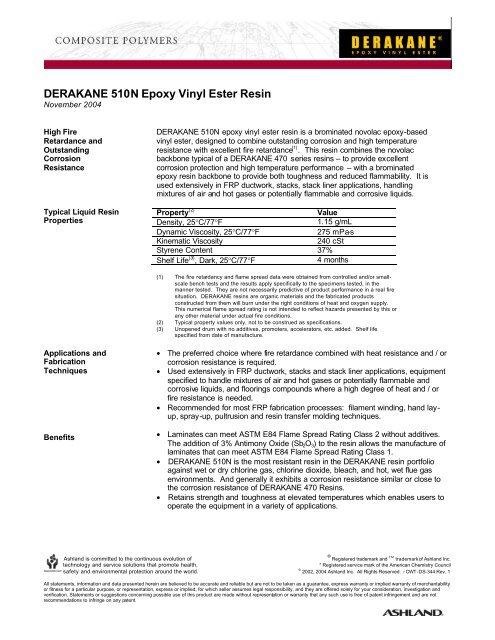

It is a resin used when both chemical resistance and flame retardancy are required.

Epoxy polyepoxide is an epoxide polymer that cures when mixed with a catalyzing agent or hardener.

High density cross linked products are suitable for temperatures above 250 of 121 oc.

Epoxy resin have an excellent electrical thermal and chemical resistance.

Their unique combination of high hdt and elongation makes them resins of choice for applications with thermal cycling e g for chemical reaction vessels.

Their unique combination of high hdt and elongation makes them resins of choice for applications with thermal cycling e g for chemical reaction vessels.

Epoxy vinyl ester resins also find uses in coatings particulalry for the marine building and construction industries due to their excellent corrosion and weathering resistance.

They offer excellent toughness and fatigue resistance.

References and notes in some cases conventional solvents such as xylenes are also used.

Extremely chemically resistant finishes.

Reactivity vinyl ester resin that offers a high degree of chemical resistance and toughness.

Standard epoxy vinyl ester resins are limited to 220 250 of 104 121 oc in most applications.

Polives 721 epoxy novolac based vinyl ester resins are.

Are low styrene monomer bisphenol a epoxy vinyl ester resins with mechanical thermal and chemical resistance properties between derakane 411 and derakane 470 resins.

It s high retention of strength and toughness at higher temperatures makes it ideal for flue gas applications.

Derakane and derakane momentum 411 resinsare the globally recognized standard for epoxy vinyl ester resins.

It is common to increase the strength of epoxy with fibrous reinforcement or mineral fillers.