Incorporating ethylene vinyl acetate eva copolymer in the pama is also another modification strategy which is useful in the heavy fuel or crude oil flow improver application.

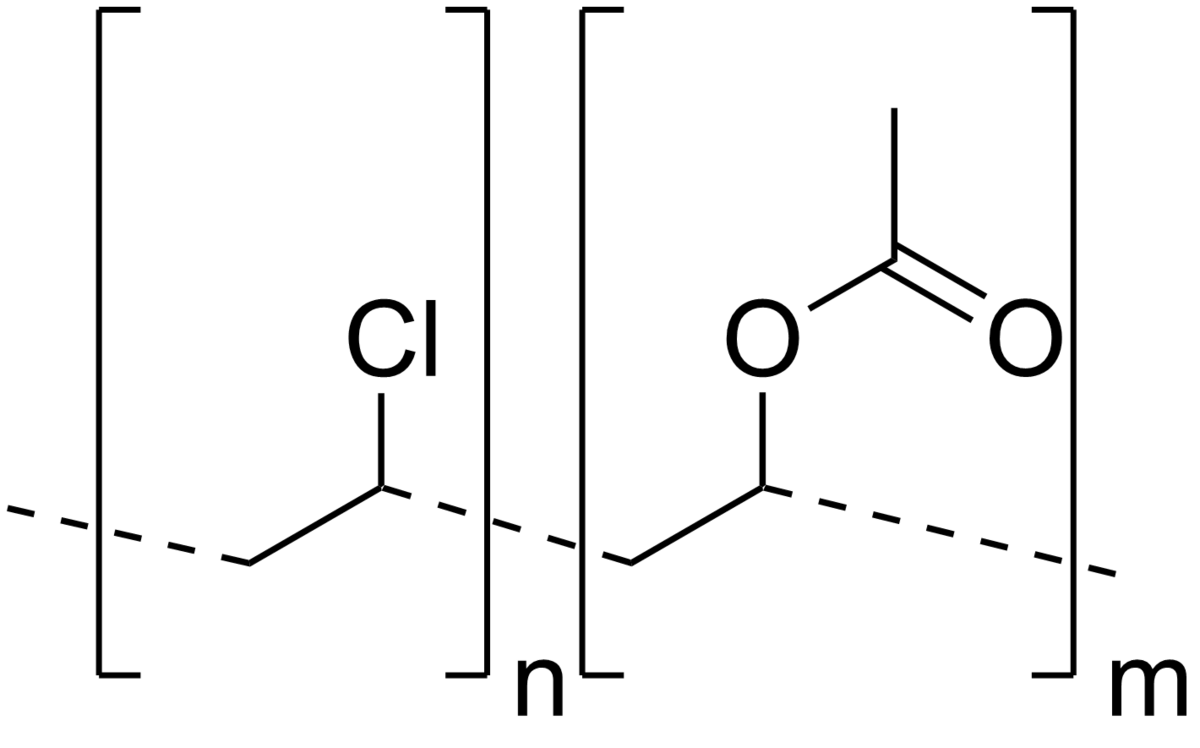

Ethylene vinyl chloride copolymer.

Kanevinyl m series which is a vinyl chloride vinyl acetate copolymers has outstanding fluidity in its molten state and is suited to processing at low temperatures.

26 eva copolymers usually comprising a vinyl ester content of 15 40 have been identified to be effective flow improvers for crude oils and middle distillates.

The vinyl chloride ethylene copolymer content of the aqueous extract can be determined by determining the organic chlorine content and calculating the amount of copolymer equivalent to the organic chlorine content.

Aqueous emulsions containing an ethylene vinyl chloride evcl copolymer and tetramethylol glycoluril are described for use as binder compositions suitable for application onto nonbonded filter paper.

It is not vulcanized but has some of the properties of a rubber or of plasticized polyvinyl chloride particularly at the higher end of the range.

Due to its chemical structure the ethylene vinyl acetates range.

Vinnol 4500 an aqueous ethylene vinylchloride copolymer dispersion can be used in applications requiring good flexibility and water or alkali resistance.

Vinyl chloride is an organochloride with the formula h 2 c chcl that is also called vinyl chloride monomer vcm or chloroethene this colorless compound is an important industrial chemical chiefly used to produce the polymer polyvinyl chloride pvc.

3 vinyl chloride ethylene copolymer content of aqueous extract i principle.

The eva copolymer which is based on a medium proportion of va approximately 4 to 30 is referred to as thermoplastic ethylene vinyl acetate copolymer and is a thermoplastic elastomer material.

Ethylene vinyl acetate eva copolymers ethylene vinyl acetates are leading polymers for hot melt manufacturing due to their high versatility.

It also has excellent stretch properties at high temperature making it ideal as a material for secondary processing such as vacuum molding.

Eva based hot melts are able to fulfill various requirements in applications such as packaging bookbinding or label sticking.

This article is cited by 32 publications.

The emulsions are prepared by incorporating 4 to 10 wt tetramethylol glycoluril based on the total weight of the emulsion copolymer into an aqueous disperson of a copolymer consisting.