Due to its various advantages sheet metals are widely used in manufacturing industries.

Explain sheet metal working process.

This process is used to remove sharp edges.

The sheet metal is placed over a die block at which point a punch presses down onto the sheet metal.

Industrial sheet metal cutting operations such as this will usually incline the punch so as to reduce the maximum force needed by distributing the required force over the cutting stroke.

Bending doesn t actually create holes in sheet metal.

The process of shaping metals into semi finished or finished forms by passing between rollers is called rolling.

All cars bodies metal doors fan blades metal desks etc.

It is employed to convert metal ingots to simple stock members like blooms billets slabs sheets plates strips etc.

Processes and sheet metal working processes.

Ingot is the starting raw metal for all metal working process.

Mainly sheet metal process can be divided into three types.

T is the ultimate tensile strength of the metal.

Molten metal from the furnace is taken and poured into metallic moulds and allowed to cool or solidify.

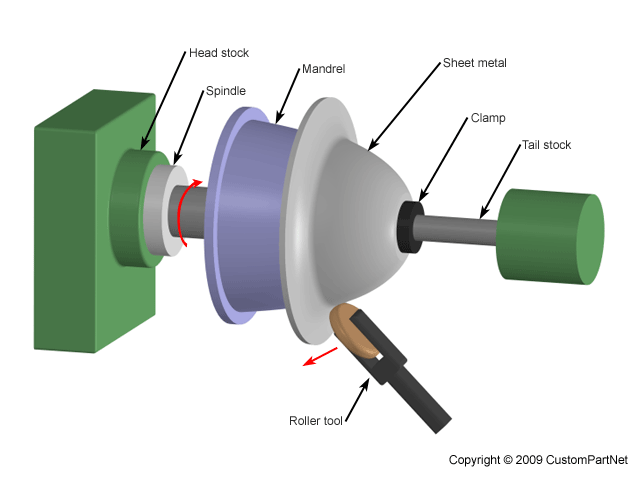

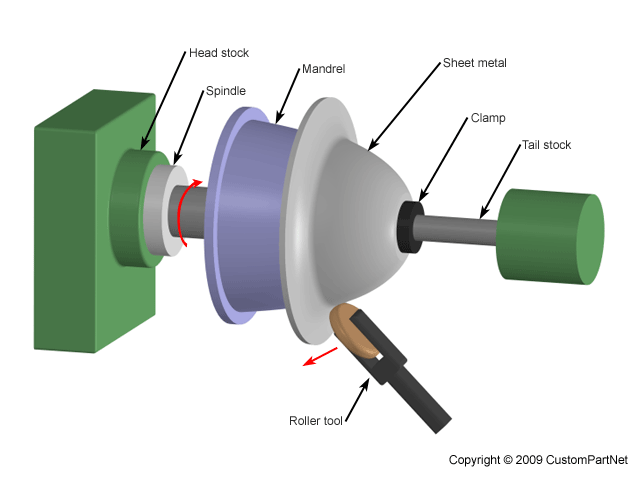

In sheet metal working the metal being processed will have a high surface area to volume ratio.

Small lengths metals are bent with.

A roll forming lines is.

Another common sheet metal forming process is bending.

The cooled solid metal mass is then taken out of the mould.

A series of bending operations are done on the sheet metal for roll forming.

Sheet metal processes are versatile processes used in metal forming industries.

This step includes bending sheet metal for creating the metal components.

In this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles.

Sheet metal forming processes bending.

Are sheet metal products.

The sheet metal is.

There are various processes to transform sheets into required product.

It is a metal working process of.

The following is a brief overview of the major metal forming processes that will be covered in detail later.

One of the simplest types of press working operations is a sheet metal cutting process called a straight cutoff.

Rolling is the most widely used metal forming process.

A punch separates a length of stock along a straight line.

Sheet metal embossing is a stamping process for producing raised or sunken designs or relief in sheet metal this process can be made by means of matched male and female roller dies or by passing sheet or a strip of metal between rolls of the desired pattern it is often combined with foil stamping to create a shiny 3d effect.

Companies typically perform bending on sheet metal using either a brake press or similar machine press.

The curling process is used to form an edge on a ring.

Bulk deformation is characteristic in that the work formed has a low surface area to volume ratio.